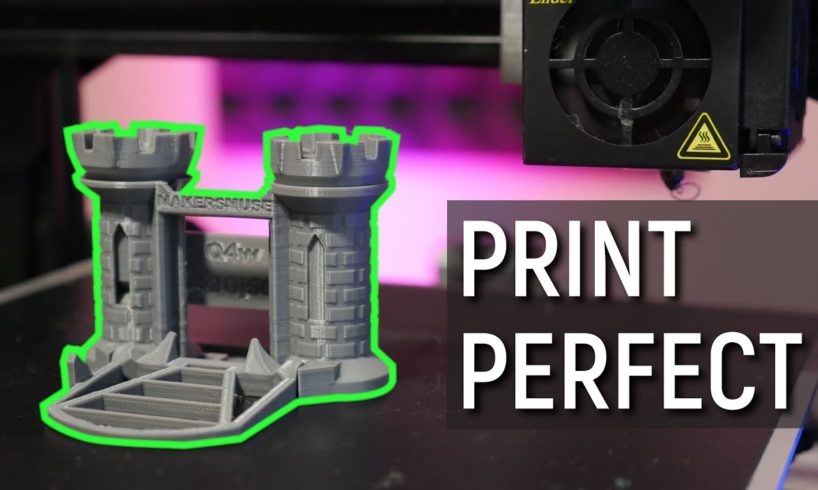

Tired of your FDM/FFF 3D Prints not coming out right? This video covers my detailed step-by-step troubleshooting process for remedying print accuracy woes.

Conquer the Clearance Castle – https://www.makersmuse.com/clearance-castle

Join the Maker’s Muse Community – https://www.makersmuse.com/maker-s-muse-community

TIMESTAMPS:

0:00 Intro

1:06 Bed Level + Nozzle Height

2:46 Steps per MM

4:58 E Steps

5:20 Stringing

9:01 Cooling, Overhangs and Bridging

12:37 Layer Accuracy

14:29 Horizontal Expansion and Flow Rate

16:25 Further Learning

LINKS:

Fixing “elephants foot” – https://youtu.be/zlgR3rHg4p8

CHEP Cube – https://thangs.com/CHEP/CHEP-Cube–Calibration-Cube-29638

Repetier – https://www.repetier.com/

Simple stringing test – https://www.thingiverse.com/thing:2450004

Ender 3 Cura settings for stringing – https://youtu.be/_QRb54zVPfQ

Overhang experiments using Vase mode – https://youtu.be/HZSFoFYpBaA

Teaching Tech PID Autotune – https://www.youtube.com/watch?v=qCtL0Yd_w0I

Join the Maker’s Muse Community – https://www.makersmuse.com/maker-s-muse-community

3D Printing Quick Start Guide – https://www.makersmuse.com/fdm-fff-3d-printing-quick-start-guide

3D Printer Buyers Guide – https://www.makersmuse.com/purchasing-your-first-3d-printer-fdm-fff

3D Printing Essentials – https://www.amazon.com/shop/makersmuse

source

Hey man, loving your channel. There is a lot i learn from you 😉 What (or where to download stl file ?) yellow cooling duct (at 11:45 minutes) is it you show on? I think a BIQU H2 ? I have one on my Ender 6 and as you showed in your video, my problem is the cooling air comes from one side and on the yellow one it seems to go around the nozzle ? I'm pleased to hear from you. Greetz from the Netherlands

this video is awesome, and super helpful. Just slow enough to fully digest but your still talking at a fast enough pace that im engaged. 10/10

Where did you get that caliper?

9:07 I had to create custom profiles in Cura and Prusa for my off-brand Lyme+ printer. The block cooling fans works but neither of the slicers operates the down blower.

HATE HATE HATE AMAZONE GET RICH BULL SHIT!!!!!

Step 1: Buy bambu lab

Dude you look so lovely, I can't tell why, but what a great content, God bless you, what a Chad!

Assembly will also throw you off as well, just got mine yesterday.and relisted my horizontal bar that the hot end travels on was low on the right side of the printer, had to build 2 identical spacers to lvl my bed properly, I was wondering why my bed springs were fully compressed on the right side. Great video 👍

That’s what they mean by that gradual setting 11:08

The one thing I need to know is when you preheat when you’re doing stuff like this to calibrate, do you pull the film it all the way out? Do you just pull the filament back into the tube? Where is no longer with the heating element? Or does it matter?

The biggest issue I’ve run into is clogs, and I can’t tell if I’m running to Hot! or too cool. Is 200 ok for PLA? 220 too much? 195 too cool??

If somebody said to use 230° for PLA I would do that right now but I’m not sure if that’s the right way to go since I always end up with solidified

hwo do I get the castle to print it?

Anyone know how to fix my ender 3 v2 when I start a print it just makes long plastic strands

Nice Daedric sword in the background. Did you 3d print that?

13:20 my heart was hurting as he bent the axis 😢😢

I need help with my printer printing off center and wayyyyyyy too big

I have an Ender 3 s1. It prints to a height of about 3 mm then the filament jams but the printer still keeps printing. Any thoughts. Thanks

This guide is amazing. Thank you so much for this information. I just started printing yesterday and I've just been struggling with trying to figure out what settings I need to clean up the prints and I got my machine used. I'm having fun but I don't know anyone else that has a printer in person so this is a difficult learning curve

for sure you can fix a bent lead screw. Heat and a covered hammer does the trick. 😀

Did you print your haircut?

Can i perfectly print power bank case?

Hi. I love you channel. I have setup my steps/mm on all axis with a caliper, but i cannot print objet with correct size (calib cube is 19.8). So for me it's a nonsense to setup axis "after'" printing objects. So can you (or your audience) give me some tips to found the source of the problem (slicer problem / firmware problem) ???? Thanks

this is why I kind of prefer resin, there's like only 2 things I have to deal with on the printer itself

I do enjoy your videos for sure, great job on the informations and videos all around but :

I can't say how annoyed I am year after year of people telling other people how accurate a pair of calipers are… The worst ones are digitial calipers but you need to look into the accuracy vs resolution when buying one.

Say you have a pair of digital calipers that measure down to 0,001mm, but the accuracy of that brand is only 0,2mm, which isn't uncommon. Then that means if you measure a 20x20mm cube, and your calipers measure 20.000mm, then it could be 20.200mm or 19.800mm, but if you measure 19,800mm and think it's incorrect because that's what your calipers say, then you'll be correcting for a false measurement when your part may be the right size. for example.

I can't stress enough how "inaccurate" calipers are for measuring precise distances. They maybe be ok for 0,2mm and above, but underneath those values you either need a very expensive set of calipers, of a micrometer : https://cdn.britannica.com/62/124962-004-6C8BB16F/Micrometer.jpg

Please stop abusing calipers as the best way to calibrate precise measurements.

Subscribed for lead screw

I may be over thinking things but if anybody understands the concept it is probably you…

Is a power conditioner ever neccessary for 3d printing? I'm referring to what commonly gets mistaken for a surge protector but this particular one flattens the mini power spikes from the incoming power. I use to sell them for home theater but don't know if

a. It would apply to printing and

b. If the power conditioner was ever its weight in scrap gold.

I'm curious because with so many magnets, motors and mixed voltages, I imagine it could cause some interferences.

One more, very common stringing cause – different filament residues (i.e. TPU residues in the nozzle on PLA prints are causing terrible stringing). Cold pull (or a few of them) are a must.

Oh, wow – I guess my nozzle is too close! I didn't know that was even a thing! I thought the goal was to get the nozzle as close as you can with minimum clearance of letting a piece of paper pass between and didn't know there were further considerations. This is very helpful to know as I am getting that elephant foot effect. Got some adjusting to do. Thanks for the info! =)

I know I'm super late to this but I have a question. In the string test I'm getting strings but not in a spiderweb type of outcome, more of occasional "fingers." They stick out about 20% across the gap and curve upwards. Is that still a stringing issue?

BTW thank you SOOOOO much for this and all your work!!!

what should i do if my bed is warped

What slicer do you use in the video

This was such a helpful video thanks! 👍

Hi, @Maker's Muse What is the Pink Mat called on Print Bed you are using? Does it help with adhesion of prints better than magnetic flex steel bed plates? If yes where can I get it? Thank you!

i have a ruby nozel that wont fit 0.4mm cleaner through it, the nozel actually measures 0.35mm,,, dam ruby nozzels.

congrats on 1 million subs

Can anyone offer advice on improving adhesion to bed for parts with a small base? I just got a printer and I had a few parts with a small base come off the bed during printing. I used a glue stick and also tried a skirt, but still had some problems. Advice appreciated, thx.